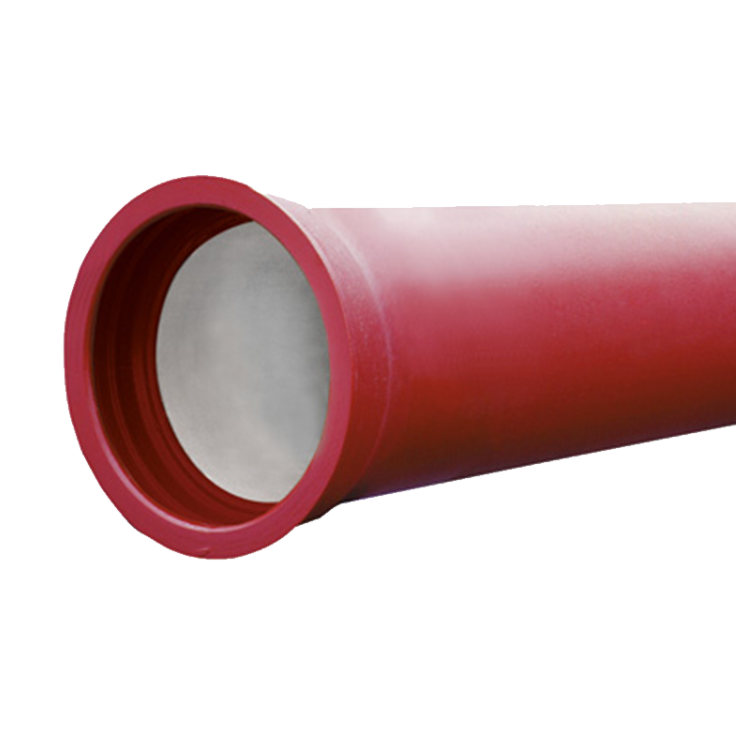

Integral® Ductile Iron Pipes – Sewer

ENQUIRE NOWSKU-DIP35100INT 100mm

SKU-DIP35150INT 150mm

SKU-DIP35200INT 200mm

SKU-DIP35250INT 250mm

SKU-DIP35300INT 300mm

For gravity flow and rising main sewerage systems

The INTEGRAL pipeline system in ductile cast iron is specially designed for gravity flow and rising main sewerage systems. It is composed of pipes of six, seven or eight metres in length with diameters of between 80 and 2000 mm, along with fittings, accessories and an associated range of valves. It is the only sewerage range with anchored joints, and allowing a rising main.

Benefits

- Strong resistance of the ductile iron pipes to chemicals, wear and tear, and high temperatures, thanks to the ultramarine blue thermoplastic polymer DUCTAN – thickness 300 microns for DN80 to 125 and the characteristic internal coating composed of high alumina cement for DN150 to 2000mm.

- Non-porous and impermeable: due to the BioZinalium external coating composed of a layer of zinc-aluminium alloy enriched with copper Zn85Al15 (Cu), with surface density of 400 g/m² covered with a protective red (RAL 3011) layer AQUACOAT 80 μm (mini average), without VOC and without BPA.

- Stability: with STANDARD push-in joints made of Nitrile, angular deflections are made possible, wich guarantees against ground movement, accidental pressures surges, water hammer and root infestation.

- Anchoring: these pipelines can also be equipped with very effective anchoring systems, which combat hydraulic thrust in the case of networks operating with a rising main.

- Flexibility: the INTEGRAL PAM range is suitable for all types of environments and effluent, especially when used in conjunction with other protective PAM solutions.

- For gravity sewer and pressure or pumped sewer networks

- Domestic waste water

- Very hard raw water and irrigation

- For effluents between pH4 and pH12

- AS Tyton type joint in NBR (supplied by Hultec) to AS1646

- External coating: - ZINALIUM® alloy Zn85Al15 (400 g/m²) - Red synthetic pore sealer minimum 100 microns to AS3750.19

- Internal coating - High Alumina Cement (HAC) to AS3972 type GB • In conformance to AS/NZS 2280:2014

No content found

No content found